- PVA SPA

- Machines

- Machine Software

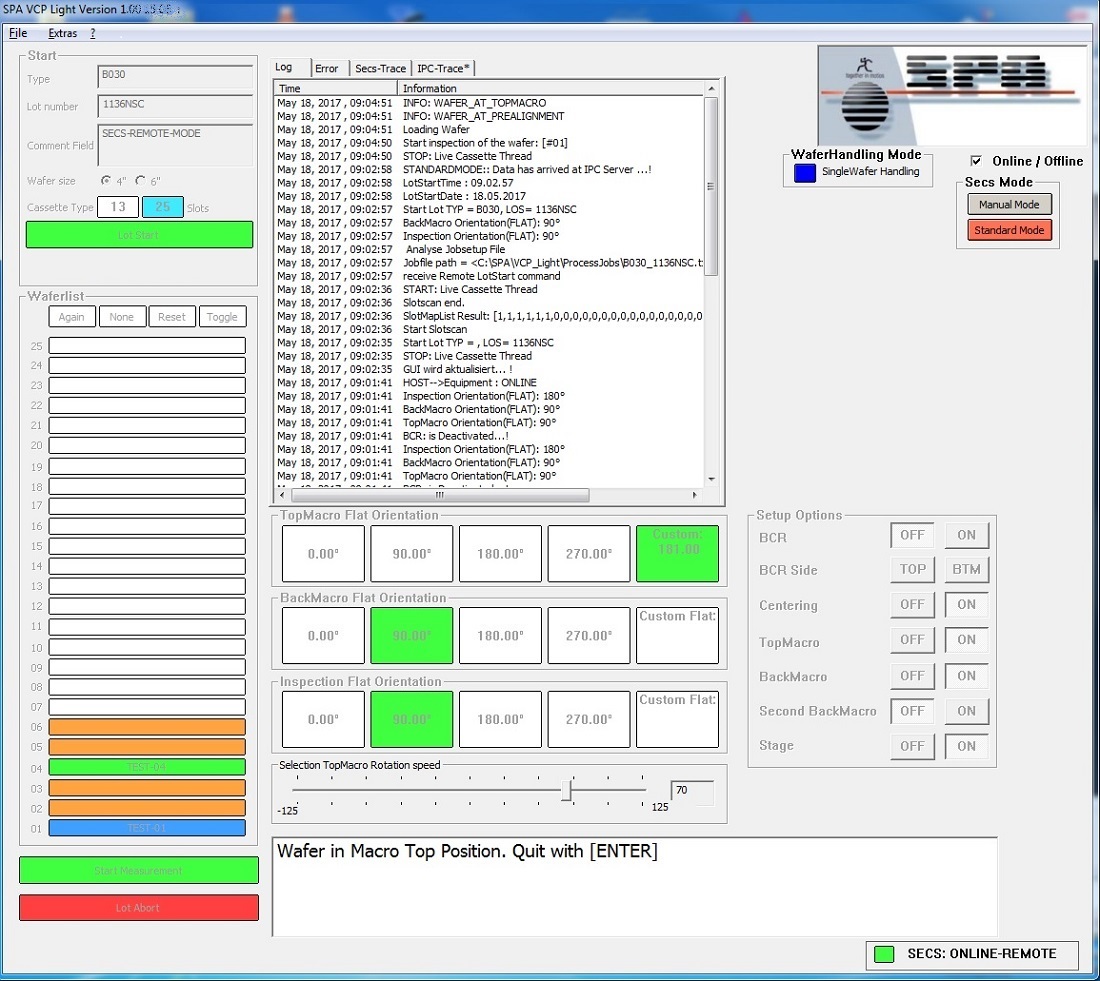

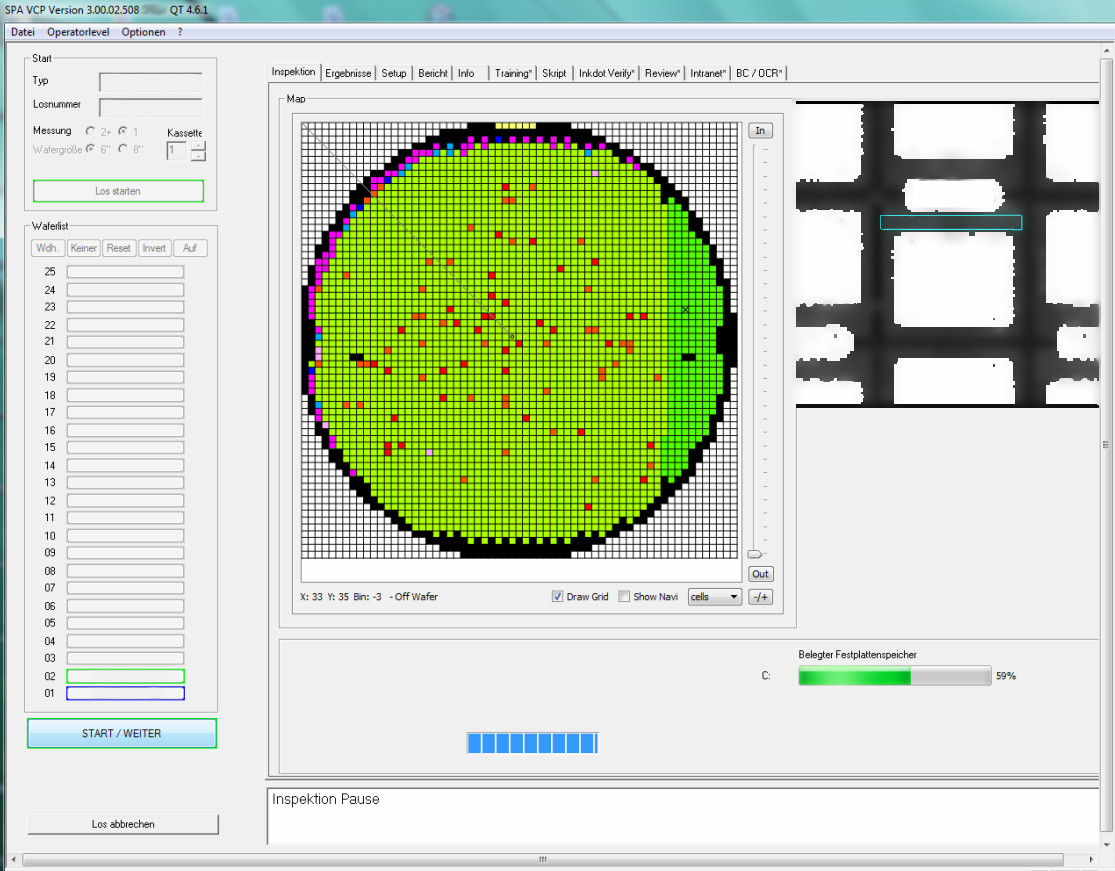

- Control software

Microscope inspection with wafermapping

VCP-control refers to the control software developed for wafermapping-based quality inspection machines. Typically this solution comes with a microscope, a motorized xy stage with vacuum chuck a wafer handler.

Feature list excerpt:

- SECS/GEM compatibility

- Recipe management (Operator / Engineer / Service)

- Slot selection (manual / sample / automatic by remote interface)

- Wafermap loading with pass/fail information (first/last map)

- Manual / automatic wafer alignment

- Temporary map save

- Map upload to network (Yes / No / Operator decision)

- Move-to-chip command by map click (chip center / relative position)

- Chip position stepping algorithms for semi-automatic inspection sequences

- Image analysis supported AOI script assignment in .setup

- Lot summary generation

VCP-ink refers to the control software developed for the SPA-Inker machine solution. It also is compatible to the derivates PIA-ink and Frame-Inker hardware.

Feature list excerpt:

- Inking and re-inking of dies according to wafer map bincodes

- Out of die center inking

- Inker cartridge limit control (dot amount, time duration)

- Inker cartridge type control via product setup and automatic detection

- Inkdot inspection settings (size, position, shape)

- Ink on pass chip detection (>50µm)

- Individual inspection parameters for edge dies and active area