We offer various outstanding software tools for your research, engineering and development in the semiconductor industry. The tools serve effectively the visualization, versatile editing and fast creation of wafer map data, as well as the precise quantification and intelligible documentation of artifacts or defects. Furthermore, our tools fundamentally ease the measurement of objects within 2D-images.

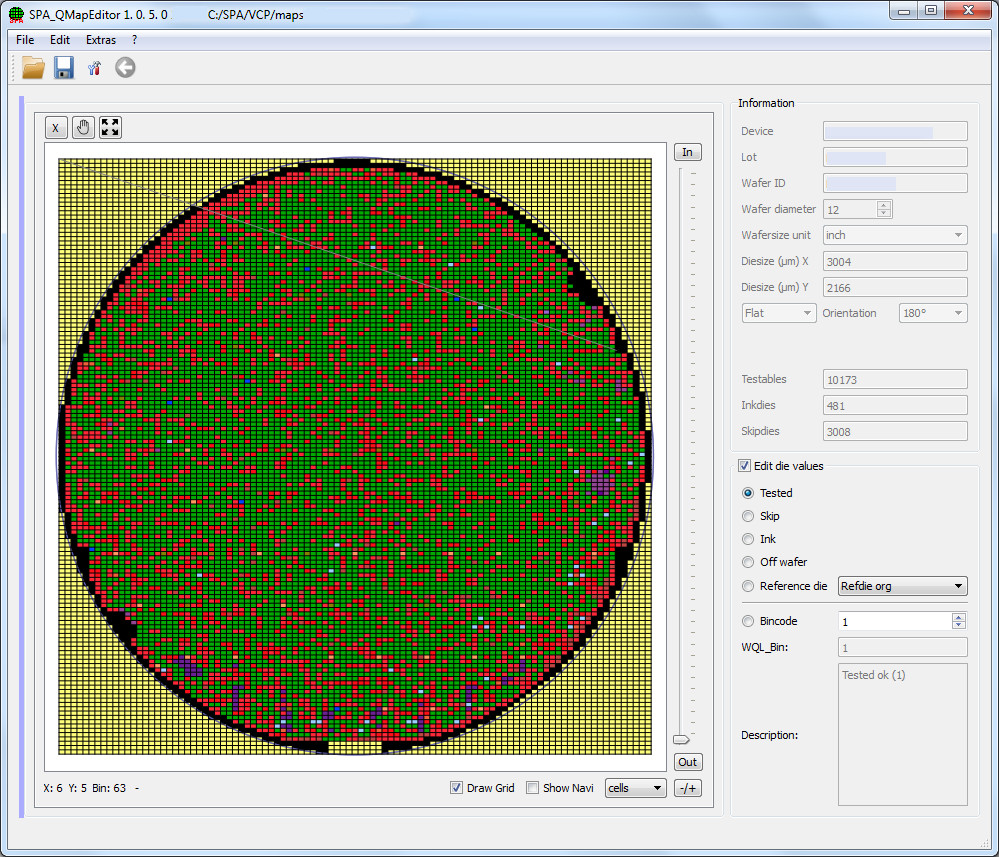

Our Wafer Map Editor allows the visual display and editing of wafer map data. The main compatible format is wql, which is expandable to any available wafer map converter.

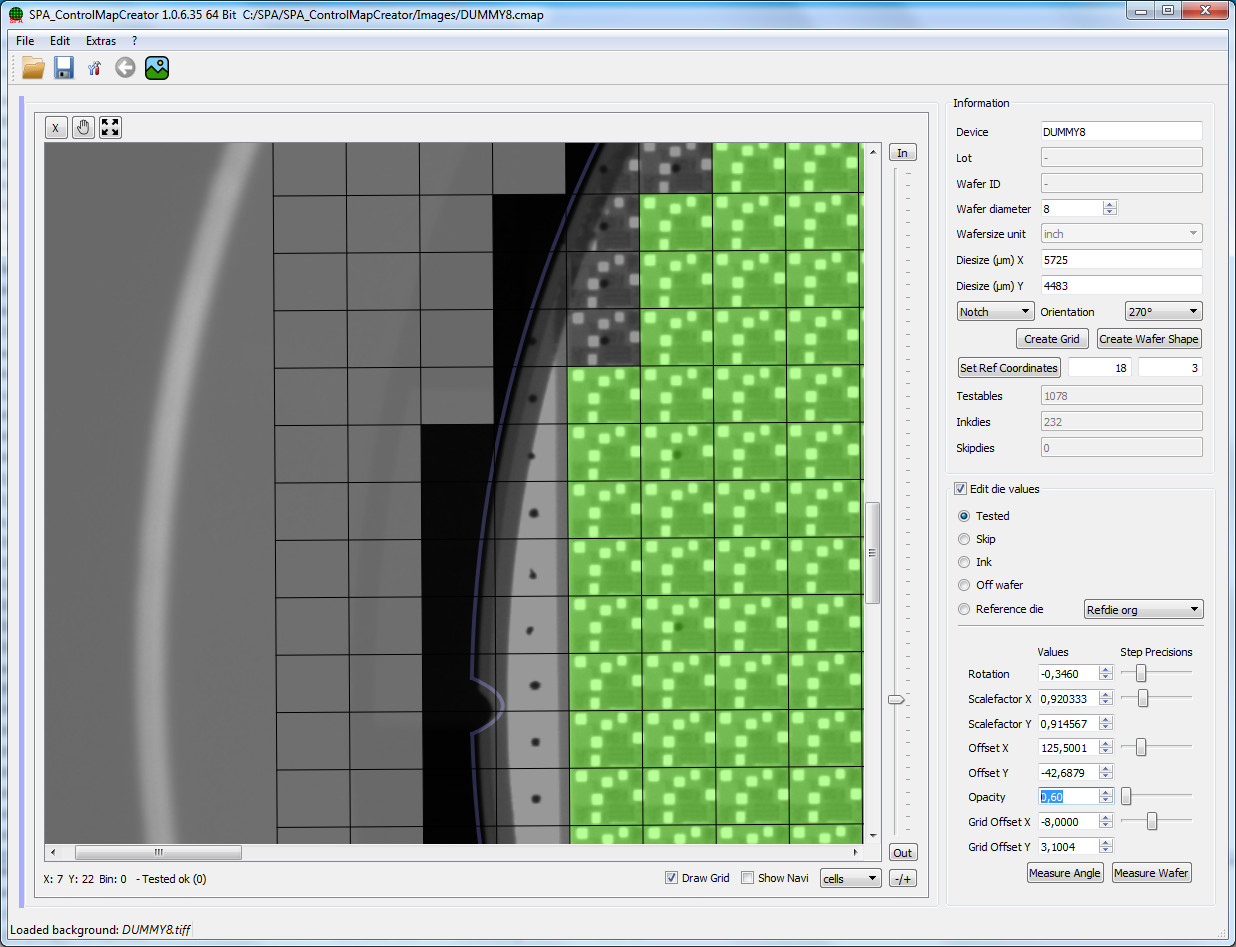

The Wafer Map Creator implies all functions of the Wafer Map Editor. In addition it allows the loading of a real wafer picture and its transparent overlay matching to a corresponding wafer map grid creation. In summary the purpose of this tool is the fast wafer map creation based on a physical wafer picture.

The Measurement Tool serves as metrology application for manual measurements on 2D camera images, which can be used standalone or as integrated part of a machine control software.

The functions of the Measurement Tool include:

- Linear distance measurement

- Area measurement (rectangles, circles, polygon)

- Free text comments

- Default text comments (e.g. usable for user instruction and information)

- Flexible color and font size definitions

- Caliper CD preset module with automatic edge detection settings

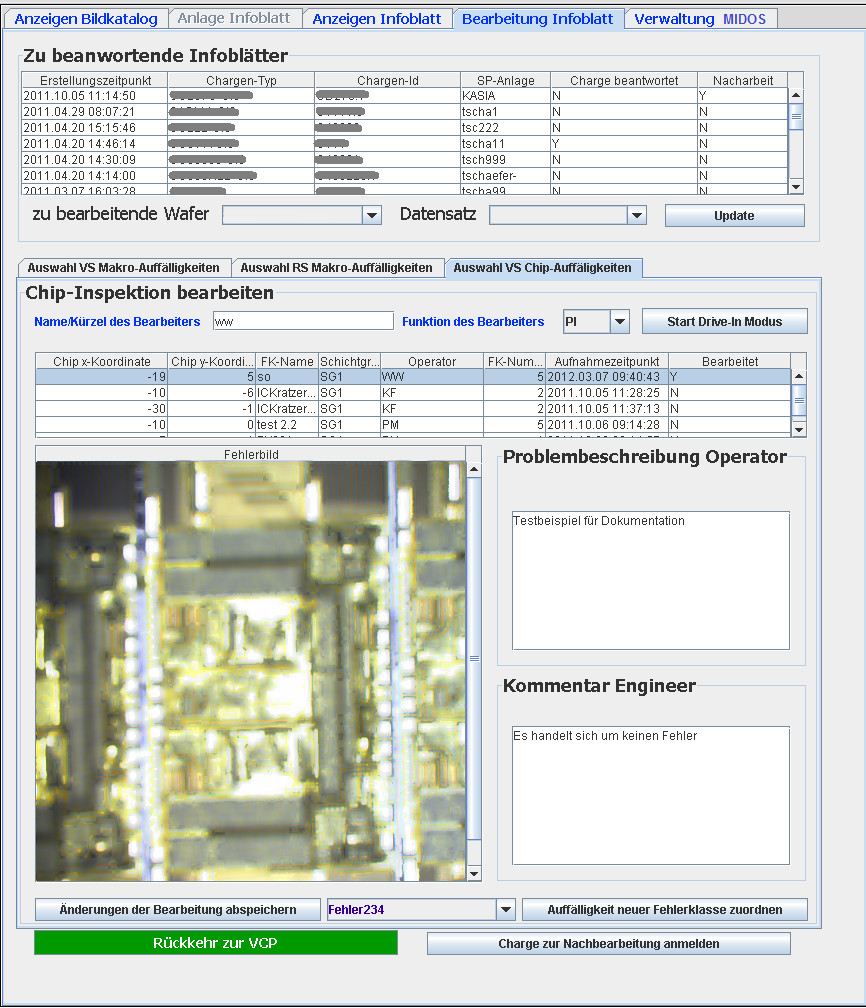

Manufacturing Information Documentation and Schooling The key purpose of MIDOS is the digital documentation of defects and unclear noticeable problems during the visual inspection of semiconductor devices.

Functions implied:

- Database connection (Oracle)

- Different user groups with different authorities

- Visualization of defect catalogue (for schooling)

- Configuration of defect catalogue by administrator

- Process-specific preselection of defect classes

- Process-specific recording of noticeable problems

- Use defect classification as process trigger (present to engineer)

- Configuration of defect classes by administrator

- Start MIDOS via link button in machine software (e.g. VCP)

- Start MIDOS as standalone application for engineering/administration

- SPECIAL: use Drive-In Mode to drive to chip defect on equipment